In the sheet metal processing field, the functionality of equipment is closely related to processing accuracy and efficiency. Today, we’d like to introduce a highly anticipated product—the custom TAM-250/4100 Hydraulic Servo CNC Bending Machine. With its exceptional performance, cutting-edge technology, and thoughtful design, it has become the “brainiac” of bending machines.

Smart Brain: DA66T System

This TAM-250/4100 is equipped with the advanced DA66T system, which acts as the “brain” of the bending machine. Whether it’s simple linear bending or complex multi-angle bending, the DA66T system handles it with ease. Operators only need to input parameters, and the system will automatically plan the optimal bending path, precisely control the collaborative movement of each servo axis, ensuring a stable and efficient bending process. This significantly enhances production efficiency and processing accuracy. The personalized OEM panel in the top-right corner of the screen integrates all the buttons for the machine tool’s functions and applications, improving operational efficiency with its flexibility and customizability.

Convenient Die Change: Hydraulic Clamping Device

Traditional die-changing processes can be cumbersome and time-consuming, but the TAM-250/4100 is equipped with a hydraulic clamping device. With just a push of a button, rapid and stable clamping and unclamping are achieved. This dramatically shortens die change time, significantly increases machine utilization, and ensures smoother production transitions.

Thoughtful Assistant: Dual-Axis Removable Front Pallet

The dual-axis removable front pallet has a load capacity of up to 200KG and a maximum tilting angle of 75°. It automatically adjusts the material support height and angle based on the shape and position of the sheet metal, maintaining excellent contact with the material at all times. This effectively prevents issues like material sagging and deformation, reduces worker strain, and makes the bending process more efficient and effortless.

Precision Guarantee: Imported WILA Mechanical Crowning

The TAM-250/4100 adopts imported WILA mechanical crowning technology, which compensates for elastic deformation between the worktable and slide during bending, ensuring each bend meets extremely high accuracy standards. This meets the rigorous demands of high-precision processing.

Flexible Positioning: 5-Axis Back gauge system and X’ Axis

The 5-axis back gauge system gives the bending machine higher flexibility. The unique X’ axis stop can move independently in the front and rear directions, making the bending and positioning of beveled sheet metal easier. This offers strong support for the processing of complex sheet metal components.

Safety Shield: Italian Imported DSP Light Curtain

Safety is a top priority in enterprise operations, and the TAM-250/4100 is equipped with an Italian-imported DSP light curtain that monitors the safety of personnel in the work area in real-time. If a danger is detected, the machine will stop immediately, providing robust and reliable safety protection for the operator.

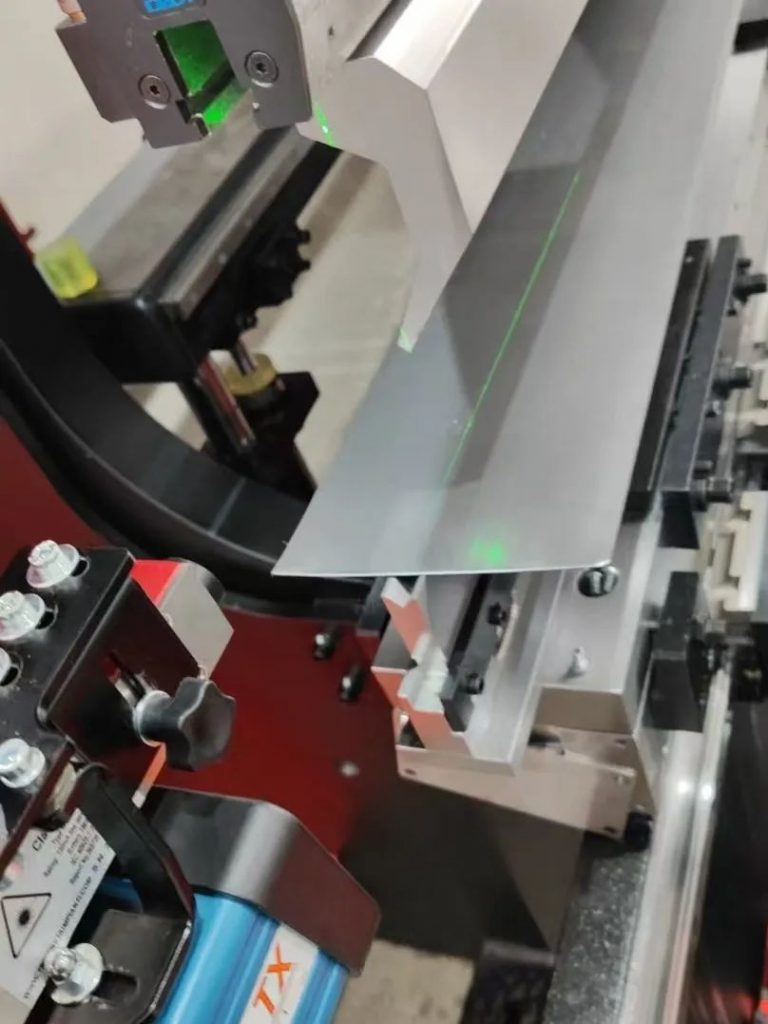

Precise Alignment: Laser Alignment Function

The newly added laser alignment function allows operators to quickly and accurately align the bending lines, achieving precise positioning. This improves work efficiency, reduces scrap rates, and makes bending processing more accurate and efficient.

Wide Applications, Strength Demonstrates Excellence

The above configurations have been widely and excellently applied in industries such as automotive manufacturing, mechanical processing, and electronic equipment manufacturing. Whether it’s large automotive body parts, mechanical equipment enclosures, or precision electronic components, the TAM-250/4100 handles it all perfectly, helping enterprises enhance product quality and market competitiveness.

Choose DERATECH Bending Machines and Open a New Chapter in Sheet Metal Processing

DERATECH CNC Bending Machines combine advanced technology, outstanding performance, thoughtful design, and reliable safety, making them the wise choice for improving production efficiency, reducing costs, and enhancing product quality. We look forward to partnering with you to open a new chapter in sheet metal processing and create a bright future together!

DERATECH

DERATECH

您好!Please sign in