In the metalworking industry, pursuing efficient, precise, and intelligent equipment has become crucial for business development. With its leading technology and outstanding product performance, Deratech continues to provide customers with more efficient and intelligent production solutions, helping companies improve productivity and competitiveness. Today, let’s explore the innovative charm of Deratech’s punching and cutting composite machine and see how this product helps you step into a new era of efficient manufacturing!

The Deratech LAP31550 and LAP31250 punching and cutting composite machines, supporting composite processing formats of 1500×2500mm and 1250×2500mm respectively, can complete punching, forming, cutting, and other processes in a single positioning. This eliminates material handling between multiple processes and multiple repositionings, not only significantly shortening production cycles but also effectively reducing the risk of processing errors. Whether it’s sheet metal processing or the manufacturing of complex components, the Deratech punching and cutting composite machine can handle it with ease.

- 30T Punching + 3kW Laser Cutting: Dual Power, Double Efficiency

– 30-ton punching capacity: The powerful punching press enables quick completion of high-precision punching and forming, meeting various processing needs.

– 3kW high-power laser cutting: Equipped with an advanced laser cutting system, it easily cuts carbon steel, stainless steel, and other materials, delivering smooth, burr-free edges and high-quality results.

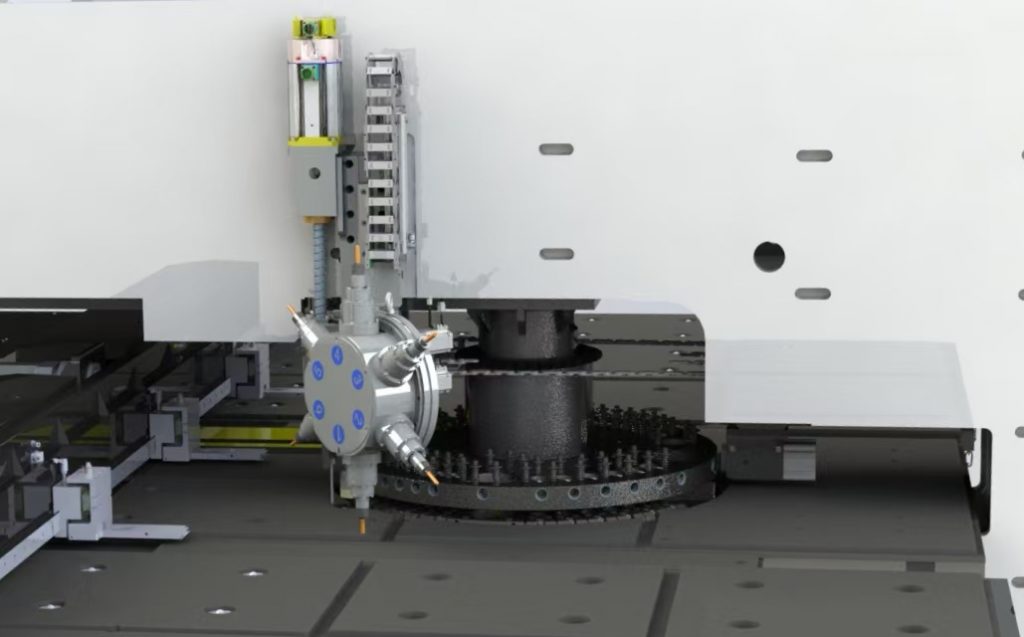

- 32-Station Turret+ Intelligent Clamps: Flexible Production, No Manual Intervention

– 32-station turret: Standard with a 32-station turret, allowing for quick switching between various molds.

– Intelligent clamp system: Automatically adjusts the clamping position and is compatible with various sheet specifications, eliminating the need for manual intervention.

- BrushInsert RollerBall Worktable: Protecting Quality, Effortlessly Efficient

The Deratech punching and cutting composite machine features a brush insert roller ball worktable that effectively protects the surface of the sheet from scratches. Coupled with a ball bearing lifting mechanism, it enhances loading and unloading efficiency, making the production process easier and more efficient.

- V-Axis Laser Cutting + Intelligent Part Removal System: Dynamic Precision, Effortless Material Usage

– V-axis dynamic cutting: The cutting head moves at high speeds along the V-axis, ensuring stability and accuracy when cutting complex shapes, offering excellent dynamic performance.

– Intelligent part removal system: Automatically separates parts from waste materials. After the waste material is flipped, it is directly discharged, reducing manual intervention and minimizing material waste.

- Sorting Conveyor: Automated Material Discharge, Worry-Free Process

Finished products after cutting are automatically conveyed via a sorting conveyor, even large-size parts can be efficiently transferred, reducing manual handling. This enables fully automated operation, ensuring continuous and efficient production.

- Optional Multi-Spindle Tapping Device

Customers can choose the optional multi-spindle tapping device based on production needs, completing specific tapping tasks and enhancing automation and production efficiency.

With continuous innovation in technology and outstanding equipment performance, Deratech remains at the forefront of industry development, helping companies embrace the new era of intelligent manufacturing. Whether it’s enhancing efficiency, optimizing costs, or ensuring quality, Deratech is your trustworthy partner!

DERATECH

DERATECH

您好!Please sign in