Client Introduction

Sichuan Elevator Manufacturing Co., Ltd. is located in Langzhong, a historical and cultural city in Sichuan Province, China. The company integrates elevator design, research and development, manufacturing, installation, and maintenance, committed to providing safe, reliable, energy-efficient, and environmentally friendly building transportation solutions for passengers.

Sichuan Elevator Manufacturing Co., Ltd. focuses on the installation of elevators in existing buildings. The company continuously innovates and integrates the internet into elevator technology—achieving automatic payment for elevator usage fees via “ETC” smart systems, enabling early detection of elevator malfunctions and timely elimination of safety risks during usage. Additionally, Dsk has standardized the production of external steel structure components, including powder coating processes and on-site bolt connections without the need for external scaffolding, addressing challenges such as long construction periods, significant safety risks, and high labor costs, thus reducing safety hazards.

Dsk has received multiple technical patents and innovation awards in this field and is recognized as a National High-tech Enterprise and a “Specialized, Refined, Characteristic, and Innovative” enterprise in Sichuan Province. Their products are highly favored by clients.

Client Needs

Sichuan Dsk Elevator is a long-term partner of Deratech. In recent years, Deratech has provided the company with multiple CNC machines. In early 2023, due to a sharp increase in orders, the capacity of traditional manual bending could no longer meet production demands. Learning that Deratech had successful cases of robotic bending in related industries, Dsk sought to use Deratech’s robotic bending unit to solve their sheet metal bending capacity issue. Upon receiving Dsk’s request, Deratech’s technical research team designed a multi-purpose gripper fixture to address the challenge of adapting a single gripper to multiple workpieces, and customized a robotic bending unit tailored to the customer’s needs, which was quickly delivered and put into operation.

The robotic bending unit from Deratech has been in use for over a year, significantly reducing the labor intensity of workers, saving labor costs, and increasing production capacity, with zero equipment failure. In October 2024, coinciding with the customer’s product upgrade and capacity expansion, Dsk once again partnered with Deratech and repurchased a robotic bending unit.

Solution

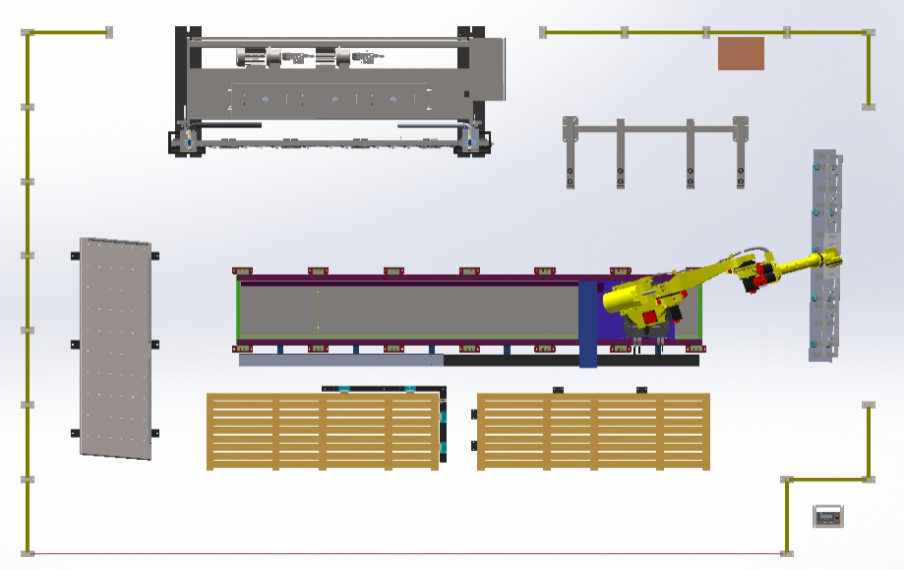

Deratech customized a centering upper and lower loading platform, gravity-centering table, and robot gripper to meet the specific process requirements of Dsk Elevator’s products. The bending machine uses Deratech’s TAM-S series high-precision bending machine, equipped with the latest Switzerland Cycelec CT12 system. This unit can automatically complete the entire process from raw material to finished bent product. Workers only need to supply the sheet material to the loading table and remove the stacked finished products from the unloading table. Additionally, the bending unit is integrated into the client’s production management system for easier production tracking and management.

First purchased Robotic Bending Unit in 2023

Repurchased Robotic Bending Unit in 2024

After quick installation, debugging, training, and acceptance, Deratech’s robotic bending unit was put into production. This purchase of a robotic bending unit by Dsk Elevator is another successful case of Deratech’s robotic bending system in the elevator industry. In recent years, Deratech has increased investment in automation R&D, building a strong, responsive automation team. Deratech not only provides robotic bending units but also offers a wide range of automation products, including laser material handling systems, CNC turret punching machine loading/unloading systems, flexible sheet metal processing lines, intelligent production management software, and more.

DERATECH

DERATECH

您好!Please sign in