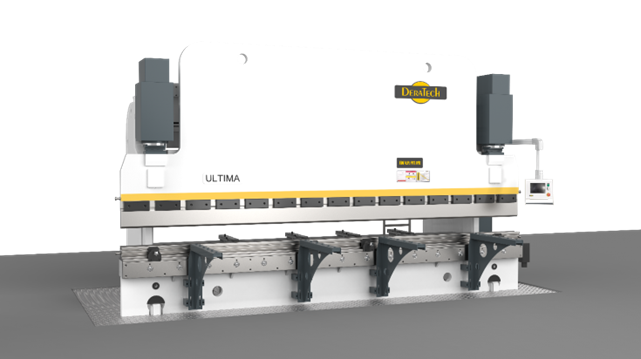

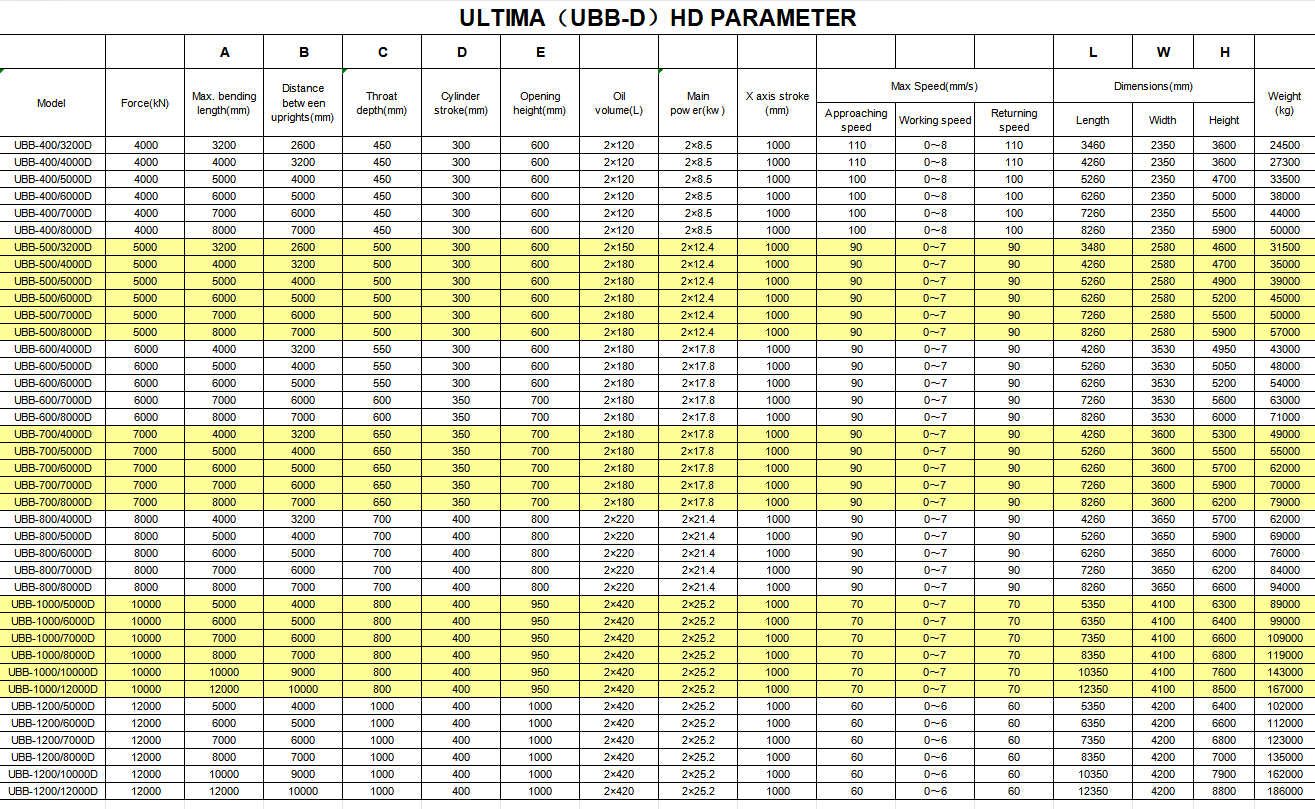

Prensa dobradeira híbrida para serviço pesado CNC da série UBB-D

Produção:

A prensa dobradeira híbrida para serviços pesados da série UBB-D adopta o sistema de acionamento híbrido óleo/elétrico patenteado pela DeraTech (Patente n.º: 201721645295.3), que é exclusiva e globalmente aplicado pela primeira vez em máquinas de dobragem para serviços pesados de grande tonelagem. Este sistema de acionamento híbrido óleo/elétrico tem as vantagens de poupança de energia, elevada eficiência, respeito pelo ambiente e resposta rápida.

- Poupança de energia: O servomotor só consome eletricidade quando dobra a chapa metálica, poupando 50%-70% de energia em comparação com as máquinas de dobrar tradicionais.

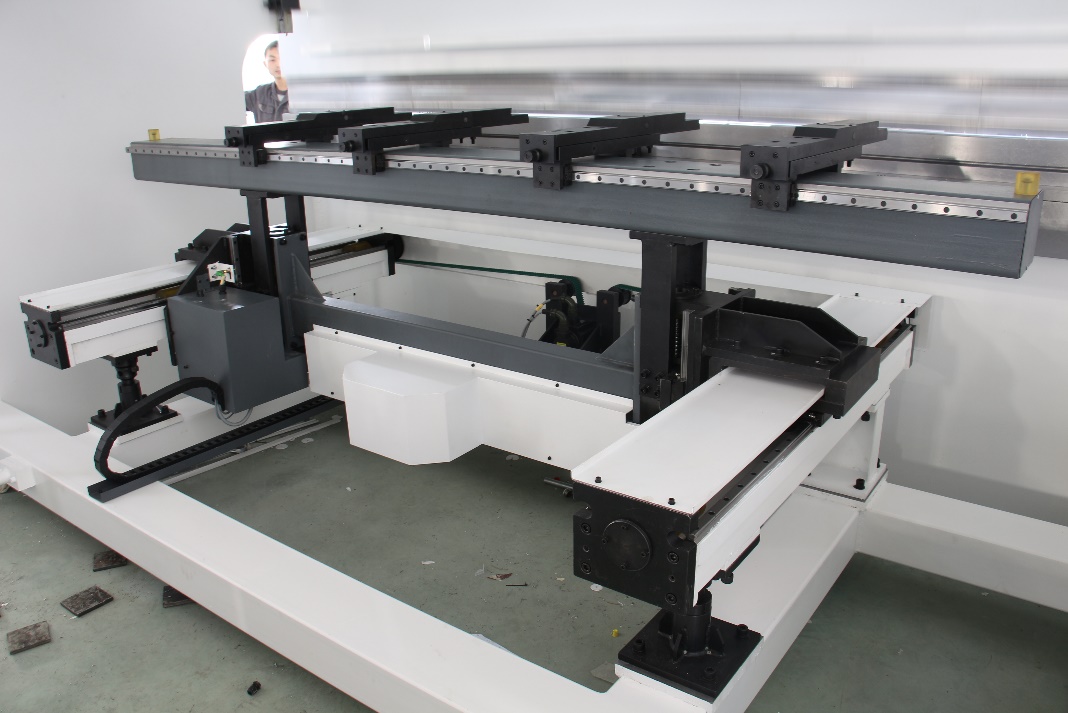

- Económico em termos de combustível: Requer apenas 1/4 do volume de óleo hidráulico utilizado nas máquinas de dobragem CNC tradicionais, mantendo um aumento de temperatura inferior, protegendo eficazmente o desempenho dos componentes hidráulicos.

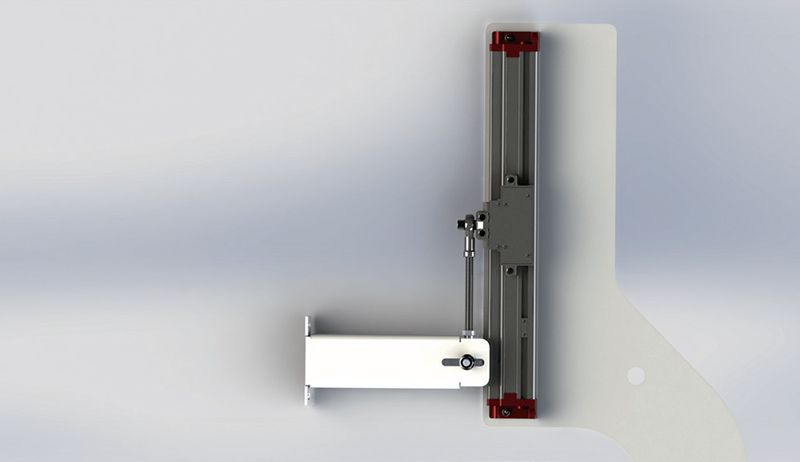

- Equipado com cilindros de óleo estruturais especialmente desenvolvidos (patente n.º: 201721644984.2)O sistema de deslizamento é suave e de alta velocidade, melhorando consideravelmente a eficiência da máquina.

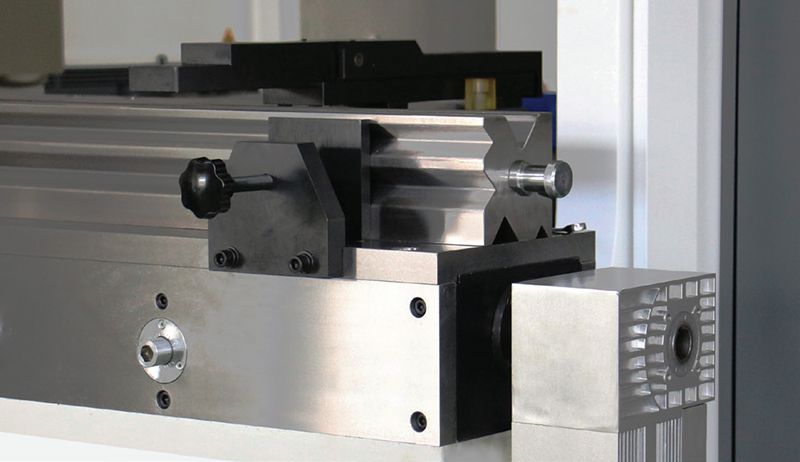

- Estrutura de inserção para a matriz inferior: A ranhura inferior da matriz pode ser ajustada de 50 mm a 200 mm, proporcionando uma operação rápida e cómoda.

DERATECH

DERATECH