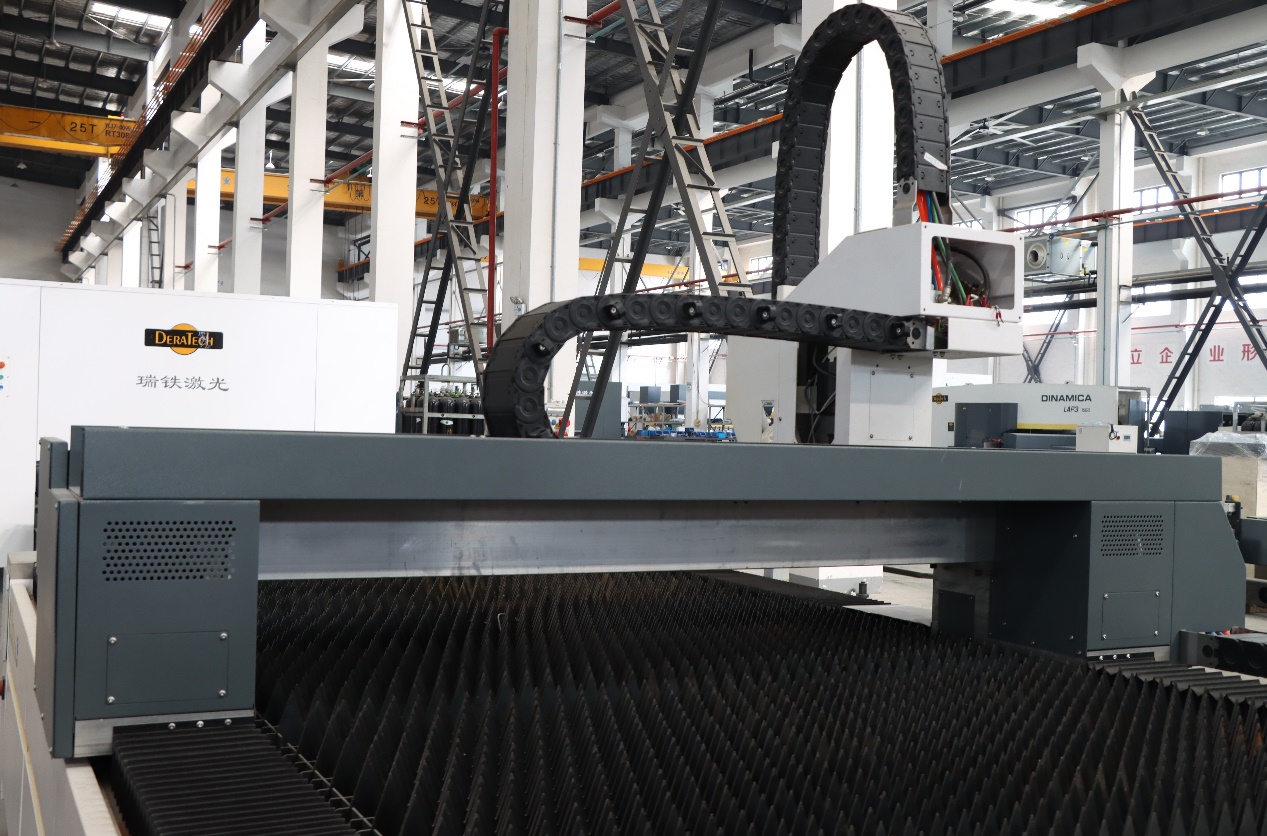

Futur S Series CNC Single Table Fiber Laser Cutting Machine

Production:

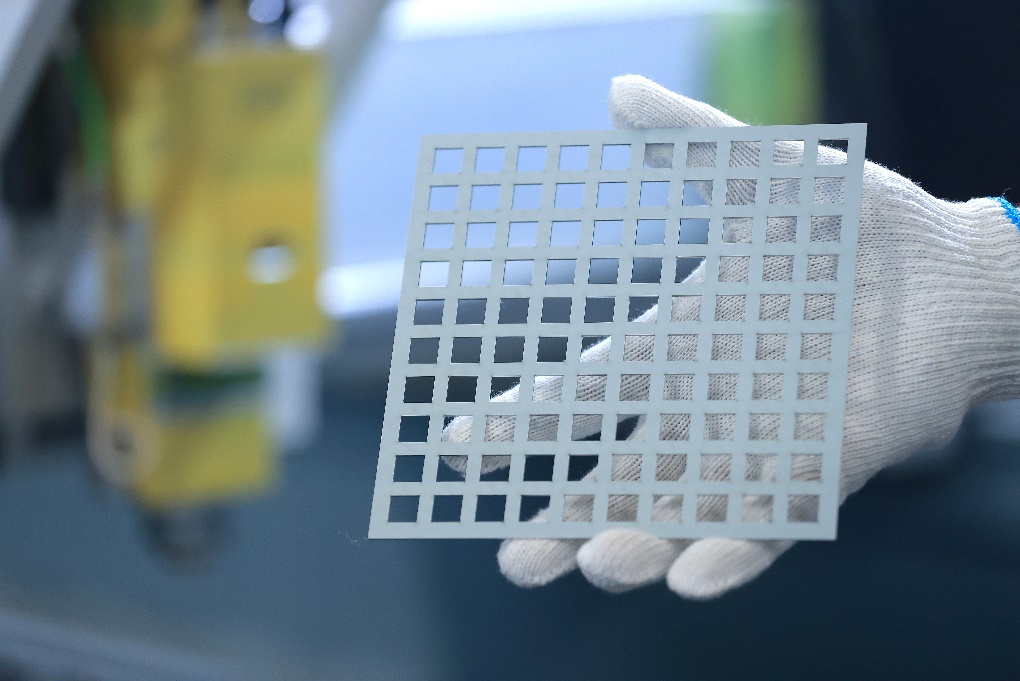

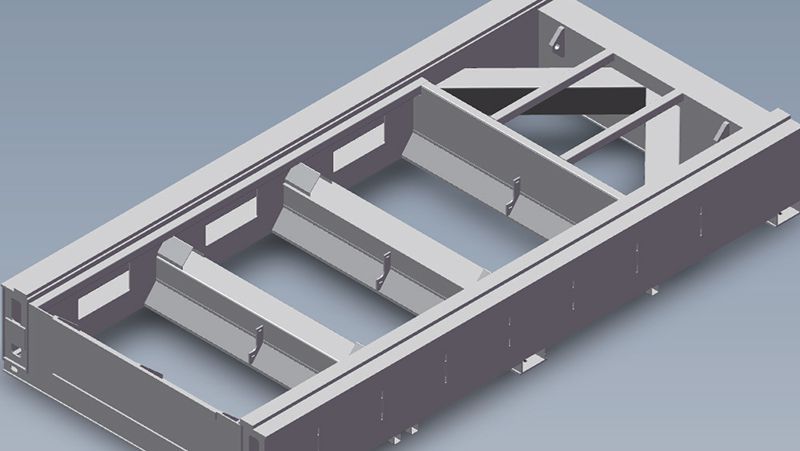

Futur S series CNC single table fiber laser cutting machine comes with a compact and simple structure. In comparison to large table laser equipment with exchange worktables, it offers significant advantages in terms of size and space, providing a “small, fast, and flexible” processing approach.

DERATECH

DERATECH